CALL: 805-232-3621

Design: Standardized Durable Transportable Self-Contained Modular Open Tool //

Platform: Interchangeable Upgradeable Extensible Serviceable // Traditional / Agile / Lean: Additive Subtractive Hybrid 3D Digitization & Validation

Intermodal Platform

for Advanced Digital Manufacturing

CAAMLS™

Conex Agile Additive Manufacturing and Logistics System

SOLUTION ID: 6422

US PAT: US10434712

AFWERX Reverse Engineering /Agile Additive Manufacturing ChallengeCAAMLS #6422

OUR SUBMISSION

Conex Agile Additive Manufacturing and Logistics System (CAAMLS™)

Conex Agile Additive Manufacturing and Logistics System (CAAMLS)

A patented mobile machine platform utilizing the intermodal shipping container to produce very large format multi-material additive 3D printers, subtractive CNC cutters, and 3D scanners in independent or all-in-one machine configuration solutions. As foundational extreme service hardware the platform is extensible and modular to add and (re)combine new 3rd party OEM technologies to enhance and/or change functionality over time. These unique capabilities will give the USAF and DoD mobile, in-theater, “on-demand and everywhere” advanced manufacturing and (reverse)engineering capabilities that are impossible with other solutions. With the Conex Agile Additive Manufacturing and Logistics System (CAAMLS), the shipping container becomes the machine; the factory and logistics are all in one. System is available now commercially to produce and ship in many configurations.

What focus area(s) does your technology/product enable USAF to do?

Additive manufacturing materials that substitute, meet or exceed original legacy material specifications, which increase physical properties, improve corrosion and temperature performance

2D to 3D conversion technology which improve upon accuracy, speed, complexity, translation, image quality and cost

State of the art technologies in reverse engineering or re-engineering

Miscellaneous

If "Miscellaneous" please describe.

Complete hybrid multi-process and all-in-one manufacturing aspect of the machine platform (additive, subtractive, 3D scan/metrology and validation, and opt. workspace) is ideal forboth agile/lean solutions and traditional industrial manufacturing. Partnering with the existing and developing OEM 2D to 3D software, process, tool head, as well as metrology technology solution providers creates a complete turn key open ecosystem solution that is transportable and deployable on both land and sea.

Solution Description

Tell us how this solution will provide USAF the capability to reverse engineer obsolete legacy parts and/or how your solution advances USAF additive and agile manufacturing efforts.

When CAAMLS is equipped with a 3D laser scanner, an automatic 3D scanning sequence turns the entire build envelope into a full digitization studio with a pre-defined tool-path for optimal data capture from all angles of the object. This tool-path can be pre-programmed for full autonomous scanning, or controlled by the user in real-time. The computer and software used to capture data are located on-board the machine where users can view and manage files before proceeding to replicate.

By using the container structure we have created the most durable hybrid manufacturing machine that is self-contained, mobile, and can combine state-of-the-art manufacturing 4.0 capabilities. The shipping container is used as a structural component requiring minimal preparation to ship or setup once delivered.

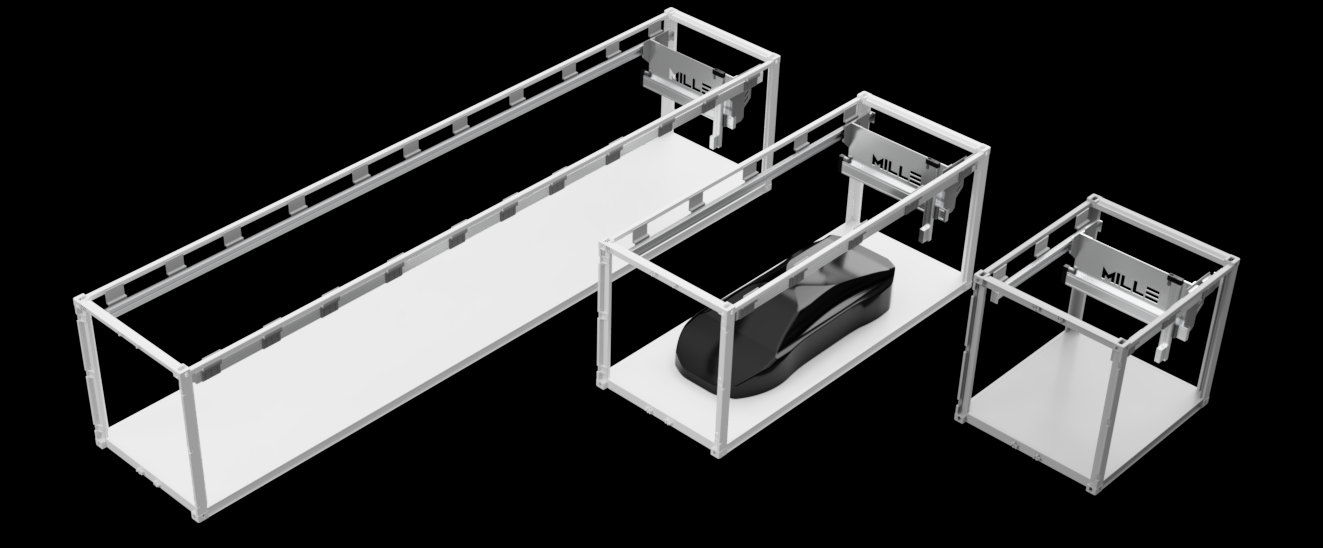

The machine combines a high strength multi-axis gantry capable of holding several tools simultaneously. Each tool represents different process capabilities and can be customized based on AF/DoD needs. Driving the machine are closed-loop servo motors for high precision and accuracy throughout the entire build area. We have expandable working volumes in standard and high cube 10ft, 20ft, and 40ft configurations offering customizable build volume, intermodal transport/storage, and user workstations ratios.

The self-contained enclosure, ECU/HVAC, and insulation packages ensure stable operating temperatures for proper layer adherence when 3D printing in thermoplastics or metal. A dedicated and/or partitioned area for operator workstations within the container can be independently temperature controlled.

Large weight and volume transport and/or storage of feedstock materials and additional equipment keep CAAMLS in operation for extended remote manufacturing processes. Air filtration, material vacuum transfer, and other equipment systems required for the operation of agile manufacturing are seamlessly integrated within the MilleBot container platform.

Value Proposition

CAAMLS’s adaptable open platform design creates high value propositions

Enclosure size and shape: self-contained, extreme service durable, standardized, intermodal transportable, modular;

Processes/tools/accessories: modular, interchangeable, upgradeable, extensible, and serviceable;

Traditional/agile/lean 3D manufacturing applications: additive, subtractive, hybrid, multiprocess, capture and validation, and workspace.

Warfighter impact:

Ability to rapidly (re)deploy and (re)constitute intermodally worldwide into extreme theater of war environments uniquely satisfies the "on demand and anywhere" requirement.

Technology impact:

Operating platform enabling technology (manufacturing + logistics) for multiple processes and 3rd party OEM tools to integrate into; largest self-contained build volume creates new application possibilities.

Efficiency:

Accommodates multiple processes/tools in one machine, utilizes the existing intermodal logistics network, does not require indoor production space; container machine can self-transport >70% of rated load in production material weight and volume.

Feasibility:

Models are already shipping and can accommodate numerous other 3rd party OEM partner solutions; self-contained; open tool head platform; user serviceable with hand tools; easy to train; knowledge is transferable across versatile yet standardized and familiar platform optimizing training and operations.

Cost/price:

Jumbo size offers the most value per work volume on the market today as well as the most mobile and extreme service solution at any price point.

Scalability: uniquely extensible universal machine platform (multiple processes and/or production unit gantries per machine) and system (multiple machines can be deployed together and formed into a work stack/cluster or distributed network across a wide area) that takes advantage of existing standard intermodal logistics, accessories, and systems; cloud computing and wireless connectivity.

MODULAR TOOL CONFIGURATIONS

Additive Manufacturing (AM)

3D Printing

Subtractive Manufacturing (SM)

3-Axis, 5-Axis CNC, Laser

Hybrid Manufacturing (HM)

Additive and Subtractive

MILLEBOT PLATFORM FUNDAMENTALS

1. Leverages existing cargo infrastructure that's unlikely to change for the next few decades

2. Combine the highest build volume, mobility, durability, and little setup time

3. Modular construction that's easy to service and upgrade with off-the-shelf parts

4. Allows you to scale production in distributed manufacturing ecosystem

KEY FEATURES

Indoor and Outdoor Operable

Corrosion Resistant ISO Shipping Container Housing

- Indoor or outdoor operation

- ISO certified ocean ready

- Stackable and scalable infrastructure

- Built-in storage for supporting equipment

Heavy Duty Gantry System

High Precision and High Performance

- Expandable build length and volume

- Several gantry configurations available

- Multi-step productionon single machine

- Easy to replace components without special tools

Sustainable Machine Infrastructure

Universally Accepted ISO Containers

The worlds' freight infrastructure is designed to move the shipping container. MilleBot transforms containers to connected advanced digital-manufacturing machines so you can leapfrog your manufacturing to the next generation and bypass traditional supply chains.

Scalable Production Volume

- Combine multiple machine units for increased production

- Deployable to most locations

- Multi-process manufacturing

Standard Machine Dimensions

10.0 x 8.0 x 8.5 ft (L,W,H)

20.0 x 8.0 x 8.5 ft (L,W,H)

40.0 x 8.0 x 8.5 ft (L,W,H)

Manufacture Anywhere

Produce Large Objects On-Demand

MilleBot's revolutionary machine platform enables next-gen manufacturing virtually anywhere. When no manufacturing infrastructure is available or logistics cost are to high, you'll be glad MilleBot has your back. Our patented mobile systems allow deployment of manufacturing units to any location at any time.

Enabling Technology

Unlock New Possibilities

Design, Prototype and create larger and faster. MilleBot turn-key systems combine everything you need to build full-scale objects enabling new innovations and applications. Combine multiple units and various tool-heads to do things never before possible.

ABOUT US

Millebot, founded in 2016, produces a commercialized mobile machine platform that utilizes the intermodal shipping container to produce custom very large format multi-material additive 3D printers, subtractive CNC cutters, and 3D scanners in many configurations. As foundational extreme service hardware the platform is extensible and modular to add and (re)combine new 3rd party OEM technologies to enhance functionality over time. The shipping container becomes the machine; the factory and logistics are all in one.